We have an option for smaller, longer tubes with thinner walls that will give your stainless steel tubes strength without compromising device design and engineering requirements. With over 30 years of manufacturing experience with 17-7 SS tubing, we can optimize your medical device design and help save costs.

Compared to 304 SS, 17-7 has multiple advantages including:

- It can be heat treated – making it even stronger and has a higher tensile strength than 304 – when cold worked

- Improved machinability

- Excellent edge retention for cutting or punching applications

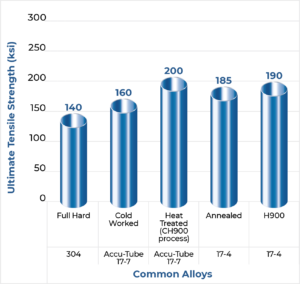

The chart below shows the ultimate tensile strength (ksi) numbers associated with common metals under certain conditions. Heat treated 17-7 stainless steel shows an increased hardness and tensile strength that can’t be achieved by cold-working alone. Use a stronger material, that’s easier to machine, for your next project.

Learn more about our 17-7 stainless steel as well as other metal tubing options for your medical device design. Contact us if you have questions on whether you should use 17-7 for your medical device project.