Is your stainless steel tube splitting during processing? Or worse, failing during clinical use?

When that happens, it’s time to contact Accu-Tube. We have the intellectual property and the expertise to engineer a high-quality, precision tube with the strength to withstand the rigors of fabrication and hold up to punishing applications like orthopedic drivers and reamers.

Our “secret sauce” is our tube draw schedule.

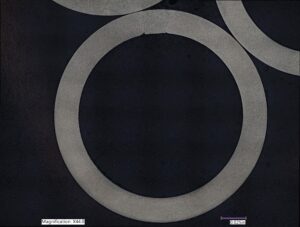

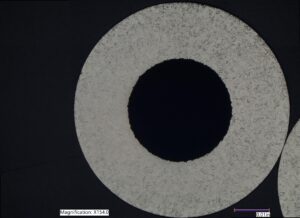

Every welded tubing provider starts with a larger-diameter tube and uses a draw process to smooth the weld seam and create the specified ID, OD, and temper (hardness). But that’s where the similarities end. Low-precision tubing might go through only two or three draw passes, without the ID support needed for precise tolerances.

In contrast, some of our tubing can go through as many as seven or eight draw passes. The tubing becomes harder with each pass, and our experienced engineers manage the annealing process to maintain the precise temperature needed to maximize strength while preventing splitting.

The extended draw process also ensures precise tolerances and helps to homogenize the weld zone. In addition, our tubing is manufactured with mandrel support on the ID and/or plug passes to maximize precise ID tolerances as well as smoothing the interior.

While two tubes at different price points may look the same on the outside, they might behave very differently in fabrication or in clinical use.

Contact us to discuss your stainless steel tubing needs. We can work with you to develop the right draw schedule “recipe” for your application, whether it requires two draw passes or eight draw passes. And once we’ve dialed in the tubing specs you need, our Hot Shop can turn around your custom tubing development run in as little as 4 weeks.