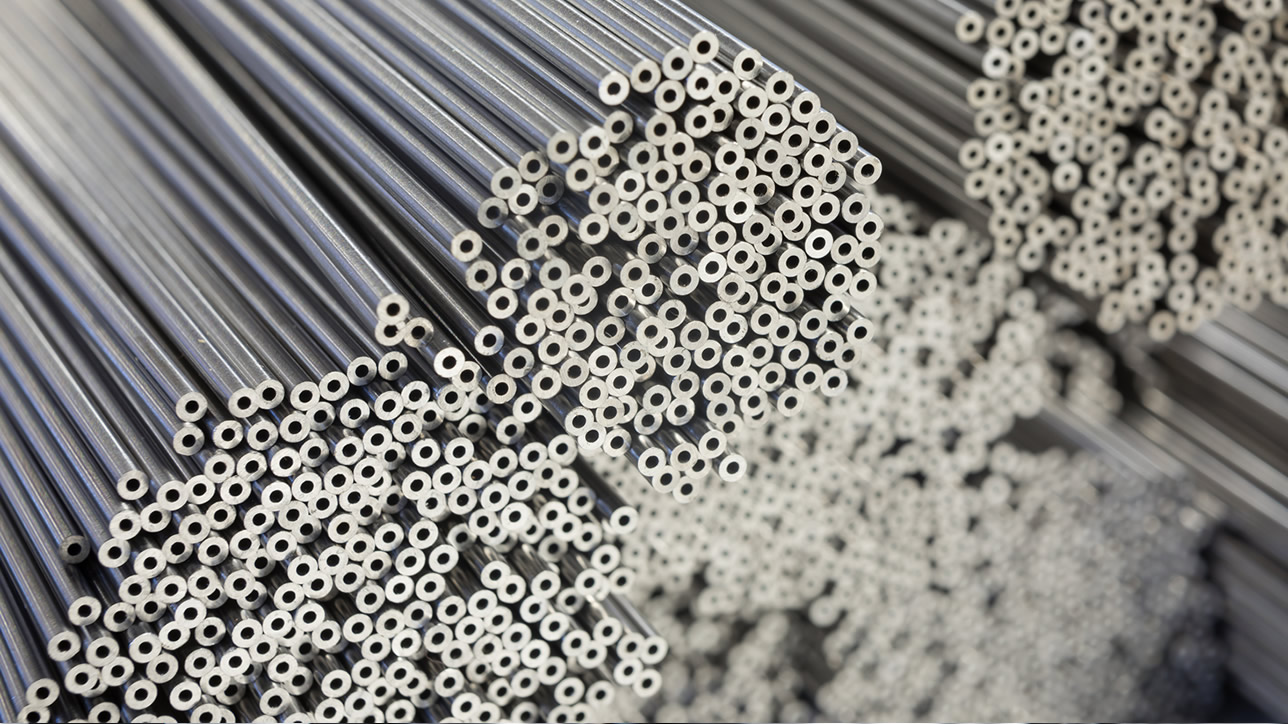

Experts in Medical Device Stainless Steel Tubing

We supply precision stainless steel tubing to medical device contract manufacturers and OEMs.

In business for nearly 50 years, we know metal tubing better than anyone. Our manufacturing processes meet stringent medical device industry requirements for formability, strength, and exceptional finishes on both the outside and inside diameter of the tube.

Our trusted stainless steel tubing is ideal for the Orthopedic, Arthroscopic, Minimally Invasive Surgical Instruments, and Diagnostics markets.

Why Accu-Tube

Medical Grades: 304, 316, 17-7 stainless steel specialization

Fast lead time for custom tubing

Centerless grinding expertise

Find the Right Material for Your Application

We combine deep materials expertise with a keen understanding of the medical device market to help you choose the right materials, finishes, and processes for your clinical application.

We have extensive experience with processing a select group of high-quality stainless steel alloys such as 17-7 that allows us to optimize cost while meeting the rigorous standards of the medical device industry.

In addition to 17-7 stainless steel, our core alloys include 304/304L, 316/316L, and 321.

Swiss-Machine-Ready Stainless Steel Tubing

We specialize in manufacturing all types of stainless steel tubing for precision Swiss machining companies. We’re one of only a handful of suppliers with in-house centerless grinding capabilities. Our experienced employees and decades of expertise give you peace of mind that our stainless steel tubing is accurate, inside and out.

- OD tolerances as tight as +/- 0.00025”

- Up to 12’ lengths available

- Clean-cut, open ends to maintain straightness

- Bar-loader-ready ends

- Enhanced ID cleanliness

- Guide bushing ready

- Custom material characteristics

Fully Scalable, From Prototype to Production

Our world-class engineering team can leverage a complete set of manufacturing capabilities to support a wide range of tubing needs, from prototype to high-volume manufacturing. Whether you need a custom prototype, finished raw tubing, or a finished component, our engineers are here to help. We’re small enough to give you the personal attention you deserve, but large enough to meet the needs of top-tier OEMs and CMOs.

How to get started

- Need prototype tubing fast? Select from a broad range of in-stock, quick-ship tubing at Chamfr.

- Need something specific? Our Hot Shop can turn around your custom stainless steel tubing development run in as little as 4 weeks.

- Not sure what you need? Learn more about how we can help you identify the right tubing for your application on our blog.

Market-Leading Quality

The medical device industry demands the highest levels of quality because lives are at stake. As an ISO-13485:2016 and ISO-9001:2015 certified manufacturer, we’ve implemented internal processes and quality systems to exceed medical device industry standards.

Tubing

Get Prototyping Tubing Fast

Select sizes are available in small quantities for quick delivery through Chamfr.com.

Shop Now